Precision, efficiency, and reliability are paramount in large-scale manufacturing. Among the various methods available, production metal fabrication stands out as a stalwart solution for crafting intricate metal components. From automotive assemblies to aerospace structures, its versatility and scalability make it a preferred choice.

Here are scenarios where metal fabrication shines brightly.

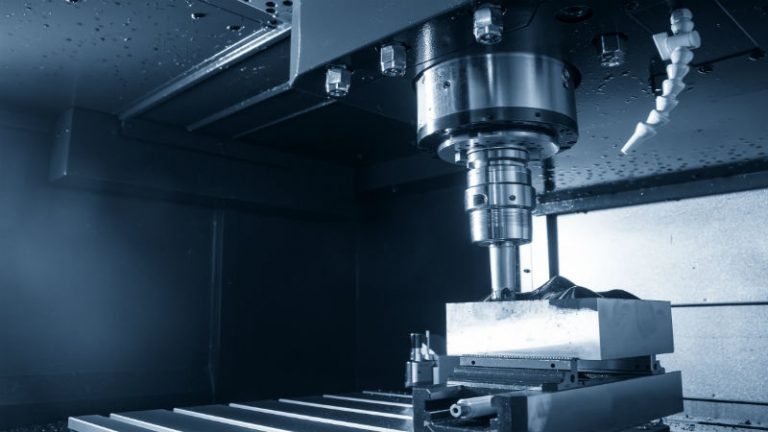

Complex Geometries Demand Precision

When your project involves intricate designs or complex geometries, production metal fabrication is indispensable. Advanced techniques like CNC machining and laser cutting ensure precise replication of even the most intricate patterns, meeting the stringent requirements of modern engineering.

High Volume Production Needs Efficiency

A metal fabricator offers unmatched efficiency for large-scale manufacturing projects requiring high-volume outputs. With automated processes and optimized workflows, manufacturers can achieve economies of scale, driving down costs per unit and enhancing overall profitability.

Diverse Material Requirements

Large-scale projects often demand the use of diverse materials to meet performance criteria. Whether it’s stainless steel for corrosion resistance or titanium for its lightweight properties, metal fabrication accommodates numerous materials, ensuring compatibility with project requirements.

Stringent Quality Standards

Industries like aerospace and defense necessitate adherence to stringent quality standards. Metal fabrication excels in meeting these requirements by employing rigorous quality control measures throughout the manufacturing process. From material selection to final inspection, every step is meticulously monitored to ensure compliance with industry regulations and customer specifications.

Contact Staub Manufacturing Solutions for quality production metal fabrication.