Clean, cost-effective, and reliable are some of the words that come to mind when discussing solvent recovery still systems. Solvent recovery for industrial or scientific purposes maintains the same objective in either case – the reduction of hazardous waste while keeping labor costs at bay. Since waste is a natural byproduct of operation, opportunities for minimization exist across the supply chain.

Waste Recycling: A Closer Look

Separating contaminants can be almost as easy as planting most kinds of seeds in soil, assuming that the optimal equipment is at hand. The process takes a sort of ‘set it and forget it approach’ until it’s complete. Through distillation, the purchased solvent is boiled to a vapor and then cooled to liquid form. What is left behind in the tank is then carefully removed with care. The leftover solvent can then be used again after collection, which is where the cost-saving comes into play.

Standard Features

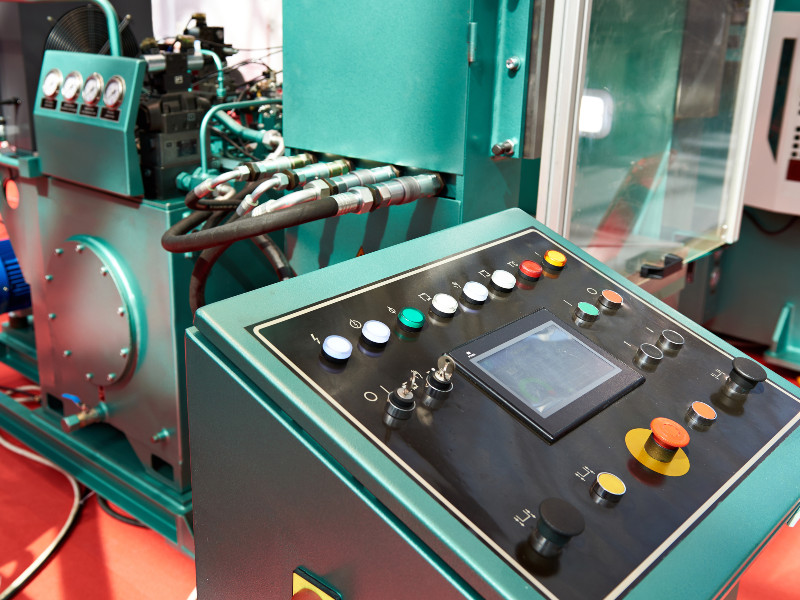

The stainless steel solvent recovery still is designed with the goal of making solid residue removal as easy and as safe as possible. The system should showcase a number of parts and accessories including bag liners for waste removal, a safety relief lid that springs into action when too much pressure builds, and an electronic control panel.

Basically, it pays dividends to be compliant and environmentally conscious. On top of that, a business that’s aware of its footprint and does something about it will enjoy a type of longevity unbeknownst to neglectful competitors.

CB Mills provides such solutions and much more. Head on over to our website and ask about how solvent recovery system can save money and time.