The world of machining is becoming high tech and computerized. If you still perform a lot of manual machining operations, you may be fine for a few years. However, many suppliers are now offering specialized parts like CNC tool holders and end mills. This is a sign of things to come and the manual shop could be left in the dust of the past within a few years time. Let’s examine some of the many benefits of CNC machining and discover why it is here to stay.

What is CNC?

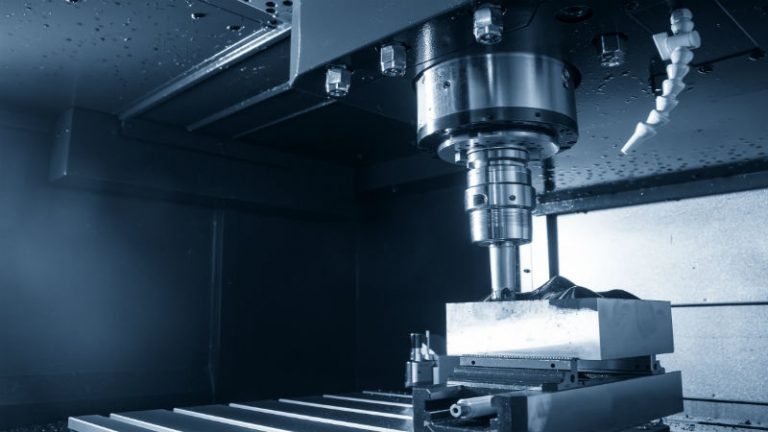

Imagine taking a manual machining operation like milling or drilling and automating it. This is what computer numeric control machining does. Many mundane and repetitive tasks can now be done by sophisticated and high tech computerized machines. For example, CNC tool holders and lathes may only require someone to feed the work piece into the machine. It can do the rest.

CNC Benefits

Here are some of the many benefits a CNC shop can expect to receive:

- 24-hour operation – if you have a lot of orders, you can run your equipment 24/7 and it will be up to the task.

- Fewer repetitive motion injuries – machines can now do many tasks which resulted in problems like carpal tunnel syndrome.

- Simplicity – these machines are not hard to run and you will need fewer skilled workers. This can drastically reduce your payroll costs.

- Greater shop efficiency – it takes a few people to do the job once done by many.

- Tool variety – many suppliers now carry several brands of CNC tool holders and other important tools for the job.

Downside

CNC machines are expensive but can eventually pay for themselves. In fact, you may have no choice, if you want to keep up with the demands of your customers.