ABS plastic, or Acrylonitrile Butadiene Styrene, is a thermoplastic with opaque characteristics, valued for its flexibility, strength, durability, and low weight. The inexpensive non-crystalline material liquefies at low temperatures and easily reforms and machines, making it a suitable option for a wide variety of applications.

A Versatile Industrial Solution

The typical polymerization process for an ABS sheet in California is through a mixture, or emulsification, of disparate products. This process frequently incorporates existing ABS plastic and lends itself well to recycling.

The Advantages of ABS Sheets

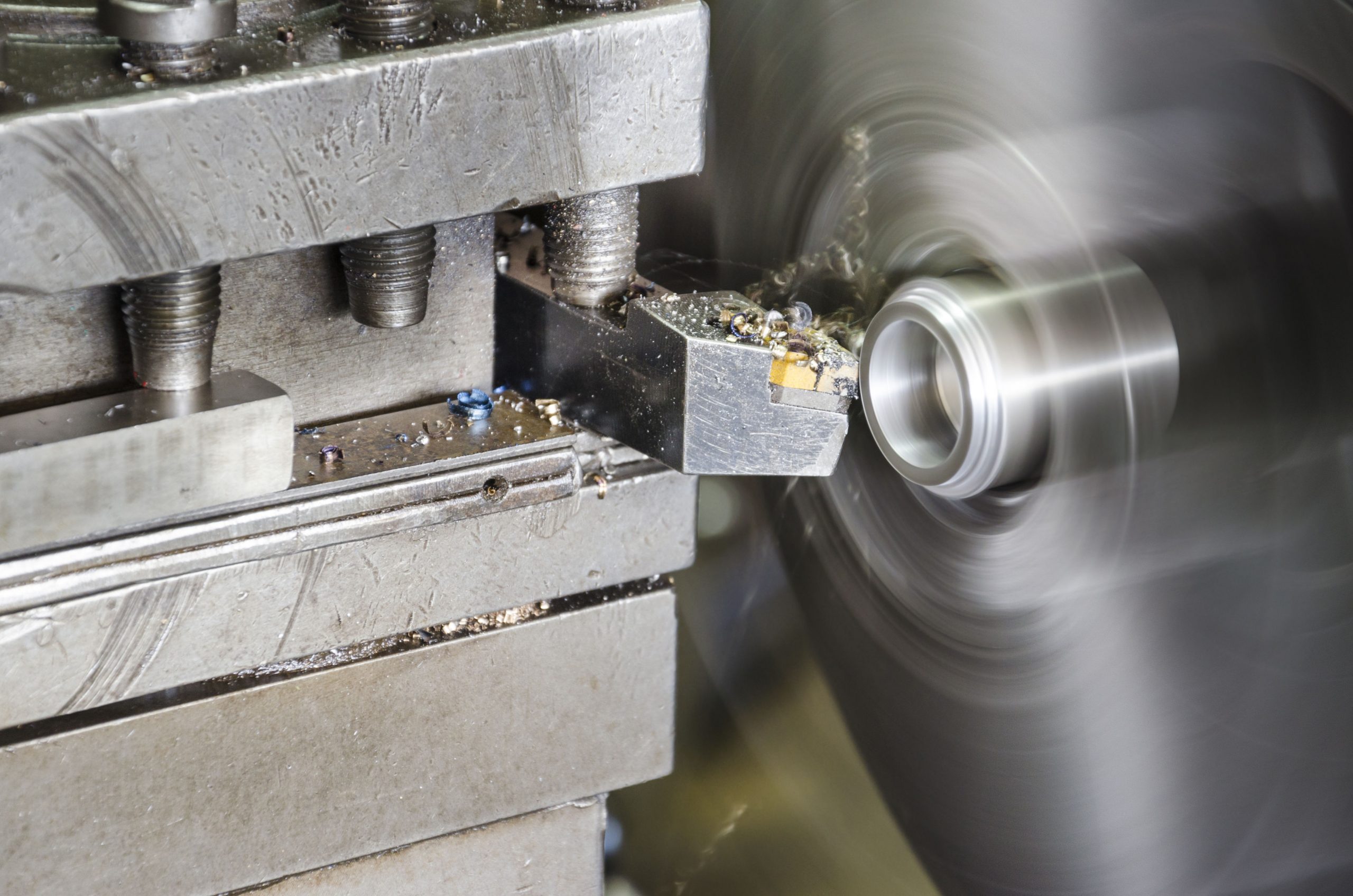

The low melting point of an ABS sheet in California makes it a good material for FDM 3D printing and injection molding. And because ABS can be easily glued, sanded, cut, drilled, machined, heat bent or painted, it’s also a common prototyping material.

ABS sheets in California are scratch resistant and have a hair-cell finish with texturing on single side. They’re a lower-cost solution, practical for molding computer keys, wall sockets, automotive trim, instrument panels and enclosures for transportation and power tools.

It has high impact resistance, valuable in face guards. ABS sheets also have the added quality of moisture resistance, useful for marine applications. And the fact that ABS comes in various colors makes it a good material for toys.

Orange County Industrial Plastics is a leading specialist in plastic fabrication and distribution. The company also provides turnkey engineering and manufacturing solutions for multiple industries. Contact the specialists at (000) 000-0000 or online via web today.