The success of your machine shop or factory may rely greatly on the type of tools and equipment you use on the production floor. When your workers are using outdated gear, they may fall behind schedule and put out a product that is poor in quality and appearance. However, when you provide them with the newest models of tools and equipment, they can put out products in a timely manner and meet or exceed quality standards for your industry.

Before you buy tools and gear like end mill bits for steel, you may want to learn as much as you can about them. You can get all of the information you need before finalizing a purchase on the manufacturer’s website today.

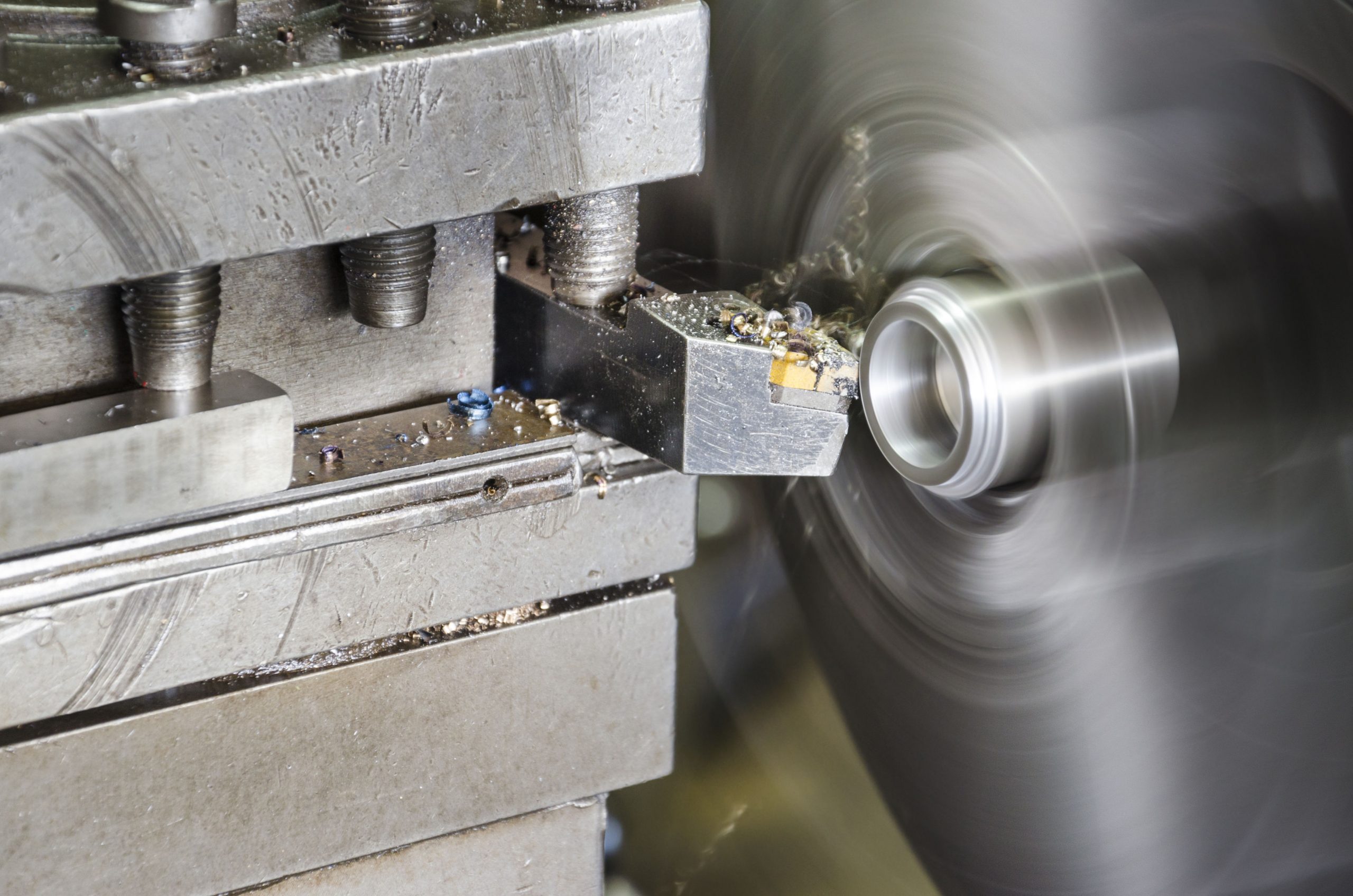

The end mill bits for steel you use in your factory will influence the quality of the product you put out as well as the speed at which your company operates. You do not want the bits to skip and skid on the metal surfaces on which your employees are working. You want the bits to make smooth contact and stay on the surface until the product is finished.

You also want the bits to be the right size for the equipment you use in your factory. These bits come in a variety of sizes and models. They may be designed for universal use or be specific to the brand or type of equipment in which it is installed. If you select the wrong size or type of bit for the machine, you could compromise the safety of the workers using it as well as the quality and appearance of the product the machine makes.

The manufacturer provides in-depth resources that provide you with all of the details you need about the bits. You can use these resources at no cost.

Upgrading Your Industrial Tools to the Newest Models

by LEVI BLUE | Apr 18, 2019 | Industrial Goods and Services

Latest Articles

- Revolutionizing Laundry Day with a Top-Quality Self-Service Laundromat in Mandarin, FL for Quick and Hassle-Free Experiences

- Crafting Unforgettable Corporate Experiences with the Expertise of a Corporate Event Planner in Orlando

- Benefits of Indoor Baseball Training in Bridgewater

- Special Considerations for Washer Repairs in Rohnert Park, CA, Rental Properties

- Combat Water Damage with Expert Drainage Services in Princeton, NJ

Categories

- Accounting (14)

- Addiction Treatment Center (1)

- Advertising (4)

- Advertising & Marketing Agency (5)

- Aerospace Parts Supplier (1)

- Agriculture and Forestry (15)

- Air Conditioning (2)

- Air Filter Supplier (2)

- Air Quality Control System (7)

- Alarm Systems (3)

- Allergy Doctor (1)

- Animal Removal (2)

- App Development (1)

- Appliance Repair Service (7)

- Aprons (2)

- Archives (1)

- Aromatherapy Supply Store (1)

- Art And Design (4)

- Art Galleries (4)

- Art Gallery (5)

- Art School (4)

- Art Supply Store (6)

- Arts and Entertainment (7)

- Arts and Recreation (9)

- Arts Organization (1)

- Asbestos (1)

- Asbestos Testing Service (2)

- Assisted Living (6)

- ATM (1)

- Auto (2)

- Auto Insurance (3)

- Auto Repair (2)

- Automation Company (3)

- Automotive (3)

- Aviation Consultancy (2)

- Awards & Gifts (2)

- B2B Lead Generation (1)

- Baby Essentials Store (3)

- Baby Food (1)

- Bail Bonds (1)

- Baseball Training Program (8)

- Battery manufacturer (1)

- Beach Clothing Store (1)

- Beauty (16)

- Beauty Care Academy (1)

- Beauty products (2)

- Beauty School (2)

- Beauty-products (1)

- Beverage Store (1)

- Bicycle Shop (1)

- Biotechnology Company (5)

- Biz Hybrid (203)

- Boat Accessories (1)

- Boat Dealership (4)

- Boat Rental Service (2)

- Boat Service (2)

- Bonds & Insurance (3)

- Bookkeeping (1)

- Breakfast restaurant (1)

- Bridal Shops (2)

- Broadband Service (3)

- Business (721)

- Business Development Service (1)

- Business Management Consultant (3)

- business services (22)

- cafe (1)

- Call Center (6)

- Camera Store (1)

- Cameras and Camcorders (1)

- Cannabis Market (1)

- Cannabis Store (2)

- Car Accident Lawyer (1)

- Car Repair (1)

- Car wash (1)

- Career Counselor (1)

- Carpenter (1)

- Carpet and Flooring (2)

- Caterer (4)

- Catholic Church (10)

- CBD Oil (3)

- Cell Phones (1)

- Cemetery Services (1)

- Certified Public Accountant (1)

- Cesspool Cleaning Services (1)

- Charitable Trust (23)

- Chef (2)

- Chemical Solutions (1)

- Child Care (2)

- Chiropractors (3)

- Church (5)

- Cleaning (16)

- Cleaning Products Supplier (1)

- Cleaning Service (52)

- Cleaning Services (13)

- Cleaning Supplies Store (4)

- Clothing Labels (1)

- cloud migration service providers (1)

- Club (1)

- Coffee Machine (4)

- Coffee Shop (4)

- College (5)

- comic book (1)

- Communication Services (1)

- community (1)

- Computer security service (2)

- Computer store (1)

- Computer Support and Services (4)

- Computers (2)

- Concrete Contractors (4)

- Construction & Maintenance (10)

- Consultants (10)

- Consulting Services (5)

- Container Supplier (2)

- Contract Manufacturing (1)

- Cooking Equipment (6)

- Corporate Entertainment Service (5)

- Corporate office (3)

- Corrugated Box Manufacturer (18)

- Cosmetics (1)

- Cosmetics & Beauty Supply (3)

- Cottage Rental (2)

- counseling (1)

- Counselor (5)

- Couple Counsellor (1)

- Credit Counseling Service (1)

- Credit Repair Services (1)

- Cremation Service (16)

- Customer Support (4)

- Cybersecurity (1)

- Dance Studio (1)

- Data Analysist (1)

- Data Management (1)

- Dating (9)

- Dating Service (9)

- Day Spa (1)

- Dental Supply Store (1)

- Dentist (3)

- Design & Printing (1)

- Design Agency (1)

- Diamond buyer (2)

- Digital design and Development (4)

- Digital Marketing (6)

- Digital Printing (6)

- Document Shredding (4)

- Dog Gifts (2)

- Dog Training Academy (2)

- Door Security Device (1)

- Doula (2)

- Doula Training (1)

- Drain Cleaning (1)

- Drink & Food (1)

- Driving School (8)

- Driving Schools (2)

- Dry cleaner (1)

- DTF Transfer (4)

- Dumpster (4)

- Dumpster Rental Services (3)

- Editing Agency (3)

- Education (44)

- Electric Motors (1)

- electric-paint-mixer (1)

- Electrical engineer (1)

- Electrical Equipment Manufacturer (2)

- Electrical supply store (3)

- Electrician (34)

- Electricians (6)

- Electronics (19)

- Electronics and Electrical (8)

- Éleveurs (1)

- Emergency Clean-up Services (1)

- Emergency Training (1)

- Employment Agency (8)

- Employment Screening (1)

- Energy (2)

- Energy equipment (1)

- Energy equipment and solutions (1)

- ENGINEERING (6)

- Engraving (2)

- Environmental Consultant (8)

- Equipment (11)

- Escape game room (1)

- Escort Service (1)

- Event (6)

- Event Planner (9)

- event planning (9)

- Event Production Company (1)

- Event Suppliers (2)

- Event Venue (7)

- Executive Leadership Coaching (1)

- Expansion Joint Repair (13)

- Eyebrow Specialists (1)

- eyebrows-training (2)

- eyecare (1)

- Farming (3)

- Fence Contractor (11)

- Fertility clinic (3)

- Fertility physician (1)

- Film Production Company (1)

- Financial Advisor (4)

- Financial consultant (1)

- Financial institution (2)

- Financial Services (10)

- Fire and Security (101)

- Fireplace Store (4)

- Fireworks Store (1)

- Fishing (6)

- Fishing charter (1)

- Fishing Store (1)

- Fishing Supplies (1)

- Fitness Equipment (1)

- Flooring (1)

- Floral Interior Design (1)

- Florist (9)

- Foam rubber supplier (3)

- Food (16)

- Food & Drink (8)

- Food Franchise (2)

- Food Service (6)

- Franchise Broker (1)

- funeral (5)

- Funeral Home (2)

- Funeral Services (25)

- Furniture (12)

- Garage (2)

- Garage Door Supplier (3)

- Garage Doors (4)

- Garbage collection service (1)

- Garden Center (2)

- General Contractors (2)

- Glass (2)

- Gold Dealer (2)

- Golf Course & Country Club (1)

- Graphic Design (1)

- Guitar Instructor (1)

- Gun Shop (1)

- Guns (3)

- Gutter Repair (1)

- Hair Care (4)

- Hair Removal (1)

- Hair Restoration (4)

- Hair Salon (12)

- Hardware Store (2)

- Health & Wellness (1)

- Healthcare (7)

- hearing aid (2)

- High School (1)

- Holiday (1)

- Hom Automation (1)

- Home and Garden (3)

- Home Appliances (2)

- Home Builders (3)

- Home Cleaning Services (1)

- Home Health Care (2)

- Home Improvement Store (2)

- Home Inspection (2)

- Home inspector (2)

- Home Remodeling Contractors (3)

- Home Security (3)

- Horse Training (3)

- Hospice (5)

- Hospitality Jobs (1)

- Hot Tub Store (1)

- Hotel (7)

- HR software (2)

- HVAC Service (5)

- Hydroponics Equipment Supplier (1)

- Image Consultant (1)

- Immigration & Naturalization Service (1)

- Industrial Equipment (15)

- Industrial Equipment Supplier (15)

- Industrial Goods and Services (11)

- Industrial Mechanical (3)

- Information Media and Telecommunications (3)

- Information Technology and Services (18)

- Installation Support And Services (1)

- Insulation Contractor (3)

- Insurance (24)

- Insurance Agency (12)

- Insurance Agent Business Service (1)

- Internet Marketing Service (5)

- Investment (10)

- IPads (1)

- IT Services (6)

- Italian Restaurant (2)

- Janitorial Equipment Supplier (1)

- Jet Skis (1)

- Jeweler (1)

- Jewelry Store (2)

- kitchen (2)

- Knives (7)

- Labels (9)

- Labor Union (1)

- Laboratory (2)

- Laboratory equipment supplier (1)

- Landscape Company (3)

- Landscape designer (2)

- Landscape Lighting Designer (1)

- Landscaper (8)

- Laundromat (5)

- Law attorney (2)

- Lawn Care (7)

- Lawn care service (1)

- Lawyers (8)

- Led Digital Billboards (1)

- Legal Services (24)

- Life coach (1)

- Lighting (6)

- Lighting Manufacturer (2)

- Lighting Store (1)

- Liquor Store (1)

- Loans (1)

- Locksmith (14)

- Luxury Holiday House (1)

- Machine shop (1)

- Machinery and Equipment (1)

- Machinery and Tools (6)

- Makeup Products (1)

- Manufacturer (17)

- Marketing (7)

- Marketing Agency (9)

- Marketing Agency | Buiness (1)

- Marketing Consultant (1)

- Marriage or Relationship Counselor (1)

- Martial Arts School (1)

- Massage Therapy (1)

- Matchmaking (24)

- Material Handling Equipment Supplier (16)

- Mattress (1)

- Mattress Store (3)

- Media Production (1)

- Mediation (1)

- Medical clinic (2)

- Medical Equipment (3)

- medical instruments (1)

- Medical School (3)

- Medical supply store (9)

- Metal Fabrication (13)

- Metal Finisher (1)

- Metal Stamping Service (3)

- Metal Supplier (3)

- Metals (5)

- Micro Fabrication (1)

- Military Equipment (1)

- Mining & Metals (1)

- Mobile Home Park (2)

- Mobile Phone Accessories (1)

- Mobile Repair (1)

- mold remediation (2)

- Monument (1)

- Monument Maker (1)

- Mortgage Lender (1)

- Motivational Speaker (11)

- Movers (1)

- Moving and Storage Service (4)

- Music School (2)

- Music Store (1)

- Musics (8)

- News And Media (2)

- Nicotine Supplier (14)

- Night club (1)

- Non-Profit Organization (8)

- Numerologist (1)

- nuts and snacks (1)

- Office Rental Service (5)

- Office Solutions (1)

- Office Supplies (6)

- Oil and Gas (8)

- Oil and Gas Exploration Service (2)

- Oil Change Service (1)

- Online Casino (3)

- Online Gambling (3)

- Online Gaming (8)

- Online Job Portal (1)

- Online Jobs (1)

- Online Study Resources (2)

- Orthopedic clinic (1)

- packaging & shipping (1)

- Packaging Supply Store (2)

- Packing (1)

- Paint Store (1)

- Painter (4)

- Painting (5)

- Painting Equipment Repair and Sales Shop (1)

- Parking (3)

- Party Equipment Rental Service (2)

- Party Planner (1)

- Paving Contractor (1)

- Personal Defense (1)

- Personal Injury Lawyer (1)

- Pest Control (7)

- Pest Control Service (4)

- Pest Control Services (3)

- Pet care (5)

- pet equipment (1)

- Pet Food (1)

- Pet Preservation Service (1)

- Petrol Pump (2)

- Pets (26)

- Pharmaceutical Chemical Manufacturers (5)

- Pharmacy (1)

- Phone Dealer (1)

- Photo Booth (1)

- Photo Shop (1)

- Photographer (8)

- Photography service (1)

- Picture Frame Shop (2)

- Pizza Restaurant (1)

- Plant Nursery (1)

- Plastic Fabrication Company (2)

- Plastic Injection Molding Service (2)

- Plastic Packaging Bags (4)

- Plumbing (8)

- Pool Cleaning Service (2)

- Pool Enclosures (3)

- Pool Maintenance (1)

- Potassium Nitrite (1)

- Pressure Cleaning Services (1)

- Pressure Washing Service (4)

- Print shop (1)

- Printers (7)

- Printing (38)

- Private investigator (1)

- Private School (1)

- Propane Supplier (1)

- Property Maintenance (1)

- Publishers (1)

- Pump Manufacturers (4)

- Radiologist (1)

- Rafting (1)

- Real Estate (3)

- Recreation (2)

- Recruiter (10)

- Recruiting Agency (1)

- recruitment research firms (1)

- Recycling (12)

- Recycling Center (3)

- Rehabilitation center (4)

- Religion (7)

- Religious Center (4)

- Relocators Franchisees (1)

- Rental Exhibits (2)

- Restaurant (23)

- Restaurant Supplies Store (1)

- Restaurants (4)

- Restoration Service (3)

- Retirement Home (1)

- Roofing (12)

- Rug Store (4)

- RV Storage Facility (3)

- Safety Products (1)

- Sales coaching (10)

- Sales Management (1)

- Salon (3)

- Salvage yard (1)

- Satellite Communication Service (1)

- Satellite Internet (1)

- School (1)

- Science And Technology (1)

- Screen printer (1)

- Screen Repair Service (1)

- Screws and Fasteners (1)

- Seafood (2)

- Search Engine Optimization Firms (4)

- Security (36)

- Security System & Services (5)

- Security System Supplier (2)

- Security Systems (5)

- Senior Care (14)

- SEO (1)

- Septic system service (2)

- Shed Builder (2)

- Shop (7)

- Shopping (5)

- Shredding Service (2)

- Siding Repair (1)

- Sign shop (2)

- Signage (2)

- Small Business (2)

- Smash Room (1)

- Social Media (1)

- Society (3)

- Sod Supplier (2)

- Software (5)

- Software Company (12)

- Solar Company (7)

- Solar Company Evansville (3)

- Solar energy company (2)

- Solar Energy Contractor (9)

- Solar Panels (12)

- Solar Power Installation (2)

- Spa (4)

- Spiritual Reader & Counselor (1)

- sports (6)

- Sports Cards (2)

- Sports Medicine Clinic (1)

- Spraying Equipment (4)

- Steel Distributor (2)

- Stem Cell Preservation (1)

- stickers (2)

- Stocks and Bonds (1)

- Stone Supplier (2)

- Storage (7)

- Storage Service (8)

- Supply Chain Management (3)

- Sushi Restaurant (1)

- Swimming Instructor (6)

- Swimming School (12)

- Systems Fabricator (1)

- Telecommunication Services Provider (3)

- Television Station (1)

- tent rental in Houston (1)

- Toiletries Store (3)

- Tower Communication Service (1)

- Towing & Recovery (2)

- tractors (1)

- Trade Show Exhibits (3)

- Trade Show Services (14)

- Trailer Dealer (4)

- Trampoline Parks (2)

- Translation Resources (1)

- Translators & Interpreters (2)

- Transportation and Logistics (2)

- Travel (6)

- Travel Agency (7)

- Tree Services (19)

- Trophy shop (1)

- Trucking (1)

- Vacation Home (1)

- Vein Treatment Center (1)

- Vending Machine Supplier (1)

- Venues & Event Spaces (1)

- Veterans & Military Organizations (1)

- Veterinarian (5)

- Veterinary Software (1)

- Video Editing (9)

- Video production service (4)

- Violin Shops (2)

- Violins (2)

- Vitamin & Supplements Shop (2)

- Vocational school (1)

- Wallpaper Boutique (1)

- Warehouse (1)

- Waste Management Service (23)

- Water Damage Restoration (1)

- Water damage restoration service (3)

- Water Filters (11)

- Water Filtration (2)

- Water Heater (4)

- Water Pump Service (2)

- Water Purification Company (1)

- Water Softening Equipment Supplier (3)

- Water Sports (11)

- Water Testing (3)

- Water Treatment (1)

- Water Treatment Plant (1)

- Water utility company (4)

- Water Well Installation (1)

- Waterproofing (2)

- Waxing Hair Removal Service (2)

- Web Hosting Company (4)

- Website Designer (2)

- Wedding Bands (3)

- Wedding Photography (2)

- Wedding Planner (1)

- Wedding Service (2)

- Wedding Venue (6)

- Weddings (9)

- Wellness Courses (4)

- Whiskey Distilling (1)

- Wholesale Battery (2)

- Wildlife Control (1)

- Window (4)

- Window Cleaning Service (1)

- Windows Installation (1)

- Wine & Spirits Shop (1)

- Wine Storage (1)

- Wine Tasting (1)

- Womens Clothes Shops (2)

- Writers (2)

- X-Ray Tubes (2)

- Youth Club (1)

Archives

- April 2025 (7)

- March 2025 (32)

- February 2025 (29)

- January 2025 (36)

- December 2024 (52)

- November 2024 (41)

- October 2024 (38)

- September 2024 (45)

- August 2024 (39)

- July 2024 (57)

- June 2024 (42)

- May 2024 (59)

- April 2024 (45)

- March 2024 (51)

- February 2024 (42)

- January 2024 (39)

- December 2023 (38)

- November 2023 (39)

- October 2023 (60)

- September 2023 (42)

- August 2023 (52)

- July 2023 (51)

- June 2023 (40)

- May 2023 (44)

- April 2023 (38)

- March 2023 (44)

- February 2023 (48)

- January 2023 (42)

- December 2022 (56)

- November 2022 (56)

- October 2022 (42)

- September 2022 (45)

- August 2022 (36)

- July 2022 (44)

- June 2022 (45)

- May 2022 (30)

- April 2022 (34)

- March 2022 (43)

- February 2022 (51)

- January 2022 (36)

- December 2021 (32)

- November 2021 (38)

- October 2021 (36)

- September 2021 (24)

- August 2021 (31)

- July 2021 (36)

- June 2021 (27)

- May 2021 (34)

- April 2021 (27)

- March 2021 (22)

- February 2021 (22)

- January 2021 (25)

- December 2020 (27)

- November 2020 (20)

- October 2020 (27)

- September 2020 (18)

- August 2020 (19)

- July 2020 (22)

- June 2020 (24)

- May 2020 (21)

- April 2020 (19)

- March 2020 (30)

- February 2020 (16)

- January 2020 (30)

- December 2019 (32)

- November 2019 (39)

- October 2019 (34)

- September 2019 (26)

- August 2019 (32)

- July 2019 (34)

- June 2019 (24)

- May 2019 (25)

- April 2019 (30)

- March 2019 (16)

- February 2019 (21)

- January 2019 (21)

- December 2018 (28)

- November 2018 (34)

- October 2018 (51)

- September 2018 (14)

- August 2018 (21)

- July 2018 (10)

- June 2018 (21)

- May 2018 (24)

- April 2018 (28)

- March 2018 (28)

- February 2018 (18)

- January 2018 (27)

- December 2017 (9)

- November 2017 (11)

- October 2017 (13)

- September 2017 (12)

- August 2017 (9)

- July 2017 (17)

- June 2017 (10)

- May 2017 (15)

- April 2017 (21)

- March 2017 (18)

- February 2017 (19)

- January 2017 (19)

- December 2016 (15)

- November 2016 (9)

- October 2016 (8)

- September 2016 (17)

- August 2016 (12)

- July 2016 (19)

- June 2016 (15)

- May 2016 (17)

- April 2016 (20)

- March 2016 (12)

- February 2016 (16)

- January 2016 (11)

- December 2015 (13)